details link:

https://www.alibaba.com/product-detail/CNC-Granite-Tile-Mosaic-Cutting-Machine_62588563365.html?spm=a2747.manage.0.0.35b371d2VEv7ZS

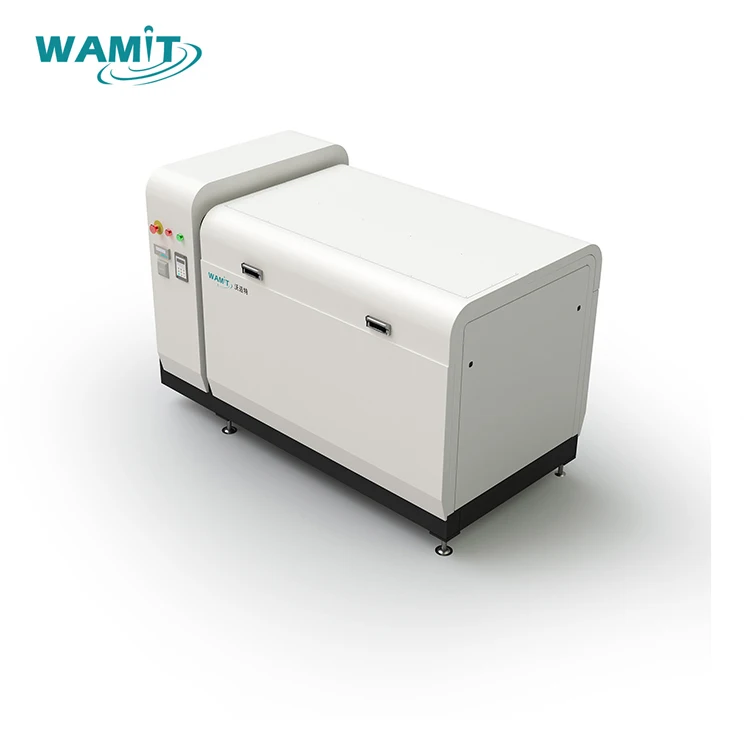

High pressure abrasive CNC water jet cutting machine for tempered glass

The gantry-style balanced design structure is more stable and improves the accuracy of the machine. Ultra-high pressure cutter head, which can be cut with pure water and sand. It has 3-axis and 5-axis cutter heads for vertical and non-vertical cutting with a maximum cutting angle of 60 degrees. The X/Y axis adopts the labyrinth waterproof and sandproof double protection system. The X/Y axis adopts Taiwan's high-quality guide rail and Swedish ball screw. It is durable and the Z-axis fully enclosed structure is guaranteed to be free from water and sand. Heavy-duty machine tools, high-temperature forging, so that the machine will not be deformed during use. China's first generation of self-designed ultra-high pressure servo direct drive pumps are more energy efficient, environmentally friendly and light, and ultra high pressure booster pumps are easier to operate and maintain. The CNC control system uses the WEIHONG professional waterjet cutting CNC system.

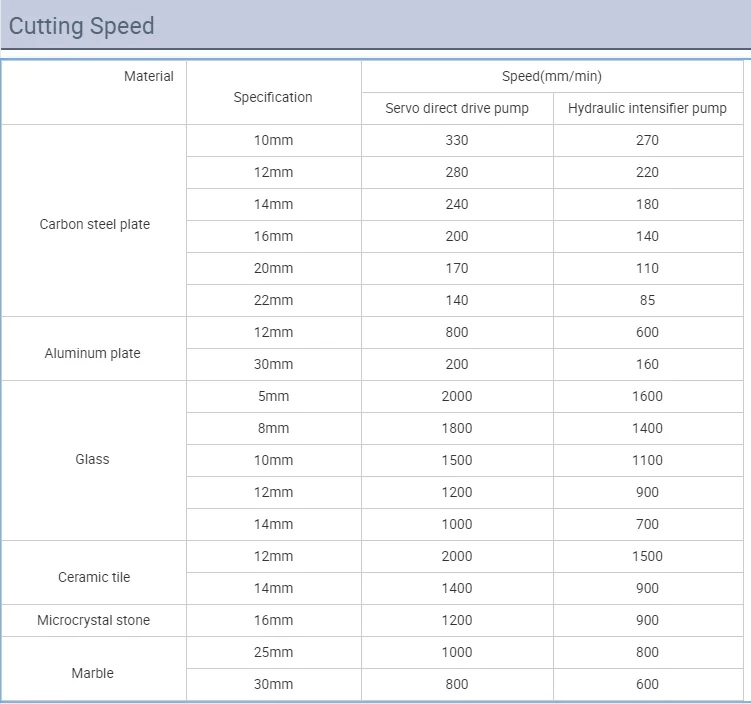

the machine moving speed can be 30m/min, will save your at least 60% cutting cost.

More advantages

1. Automatic lubrication system from the Valley of Japan.

2. The internal components are selected from Schneider International brand, with first-class quality and reliable work.

3. Way of drive : Servo ( drives and motors are from Japan YASKAWA ).

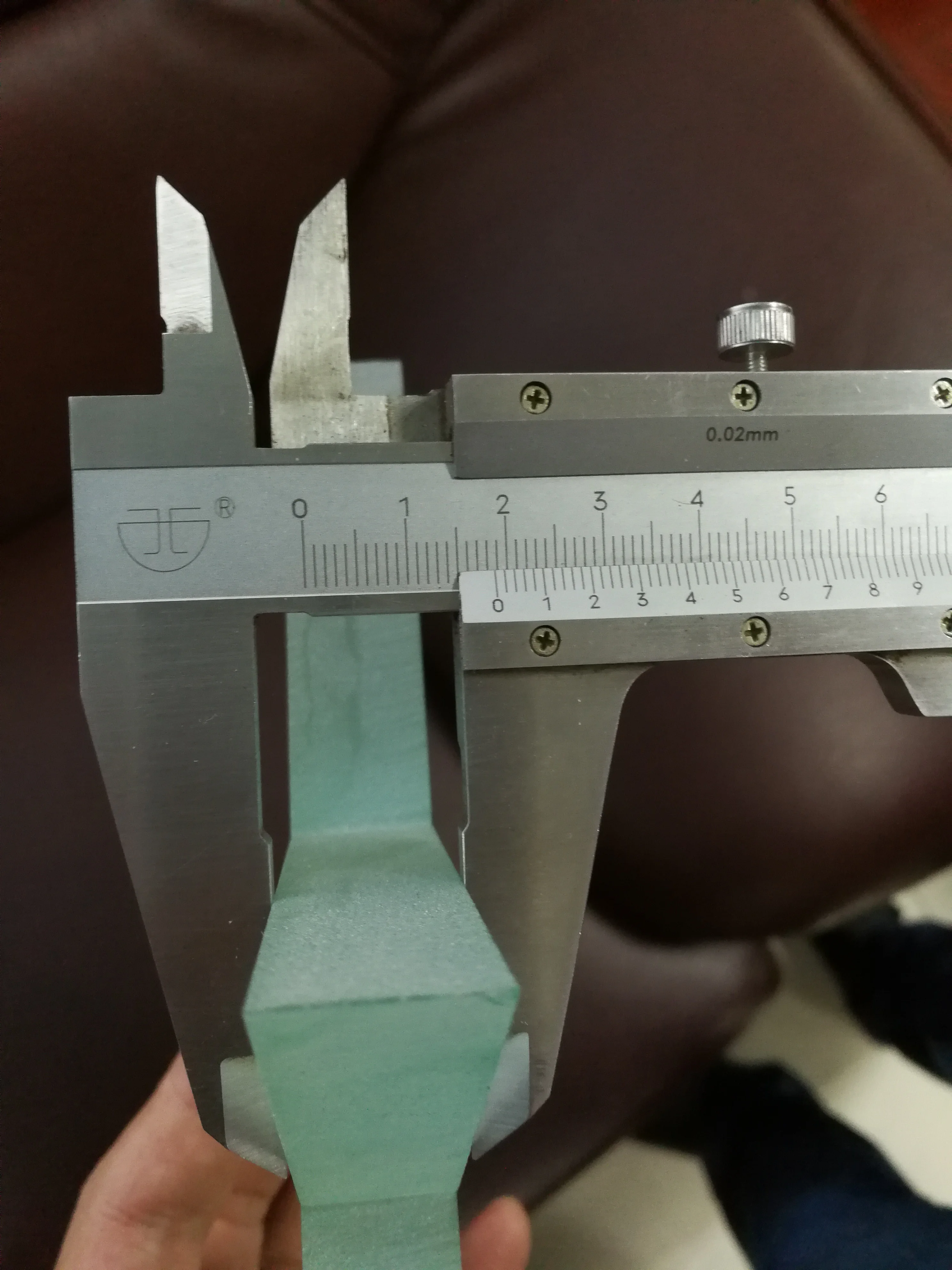

4. High precision, Ensure cutting results.

5. Provide customizable services.

6. After-sales Service: Field maintenance and repair service, Online support, Field installation, commissioning and training, Video technical support, Free spare parts.

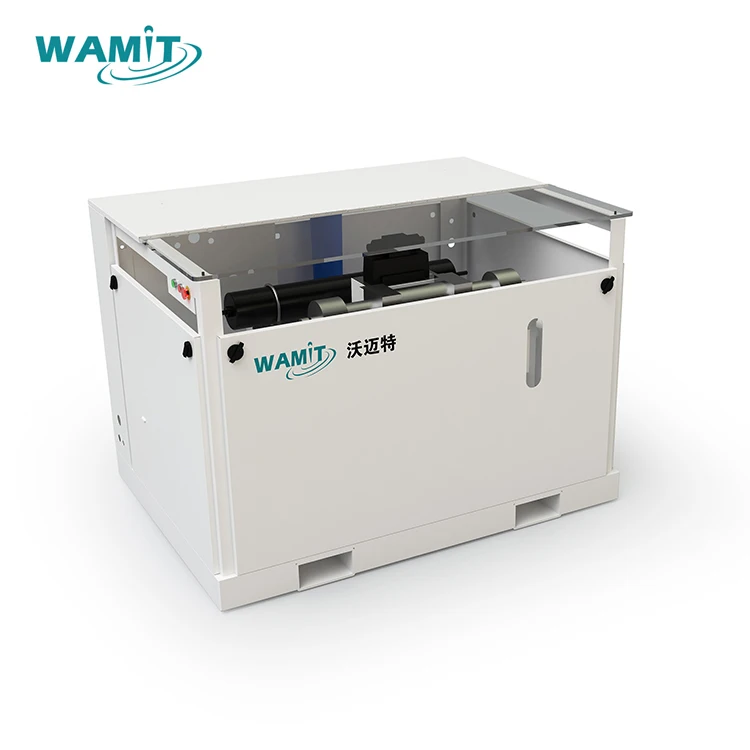

HP servo direct drive pump

(optional)WAMIT servo direct drive pump represents a new generation of high-efficiency, energy-saving ultra-high pressure pump, which is the first large R&D in China. Servo motor driven direct drive intensifier system.

Power is only 15kw, which can save you 60% to 70% of the cost

cutting speed is 20 to 50% faster than the same equipment in the market.

This is an optional pump

Model: WMT SDD 20

Maximum pressure: 60000Psi.

Gemstone aperture: 0.33mm.

Displacement: 3.0 l/min.

Inlet pressure: 0.4MPa.

Main motor power: 15KW.

Dimensions: 1680*900*1100mm

Double row water filtration system (5Micron, 1micron, series)

Intelligent start and stop function.

Over-pressure automatic shutdown and under-pressure automatic protection.

Advantages of the WAMIT servo direct drive pump:

A: Energy saving: The main motor adopts a torque motor of 15KW, compared with the motor of the 37KW hydraulic high pressure intensifier system, the power consumption can be saved by 60%-70%. B: Environmental protection: the use of servo direct drive, no hydraulic system, with self-cooling function. As we all know, hydraulic The hydraulic intensifier system must be filled with 110L of anti-wear hydraulic oil to work, and the heat generated by the hydraulic oil is also cooled by the oil cooler. The direct drive pump is completely free of hydraulic oil and cooling system. C: High efficiency: Direct drive pump provides a higher pressure output ratio, cutting speed is 20 to 50% faster than the same equipment in the market. E: Low noise: almost no noise when working. F: Small weight: The total weight of the direct drive pump is less than 600kg, and the movement is flexible. The weight of the hydraulic intensifier pump is 1000kg. G: Beautiful appearance: The structure is reasonable in design and beautiful in appearance, because the direct drive pump does not have a hydraulic system, Thereby avoiding the leakage of the hydraulic oil (the hydraulic seal will be damaged for a long time use, causing the hydraulic oil to leak), eliminates the contamination of equipment by oil stains.

HP intensifier pump

HP hydraulic intensifier pump

Maximum pressure: 60000Psi.

Boost ratio: 20:1.

Working pressure: 46000 Psi -55000 Psi.

Maximum displacement: 3.7L/min.

Inlet pressure: 0.4MPa.

Main motor power: 37KW.

With Siemens motor and Siemens high quality PLC control

Intensifier parts and pipe system (high pressure cylinder, Ceramic plunger assy, high pressure seal, low pressure seal, high pressure pipeline, check valve, etc.) Single row water filtration system (5Micron, 1micron, series) Manual voltage regulation Over-pressure automatic shutdown and under-voltage automatic protection function. A10V071 automatic variable oil pump and Schneider electrical components with high performance.

Control system

Adopt industrial PC

Dedicated water jet cutting software with graphic simulation running function, graphic input automatic programming function. • Support for DXF files. • Support forward and reverse processing functions. • Uniform speed control function. • Two modes of segmentation and smooth machining. • Automatic processing with small arc speed. • Coordinate recovery function after power off. • Double lift speed parameter function. • With cycle processing. • Convenient pause to continue and start machining in any segment. • Free time delay setting. • Apply SIEMENS PLC instead of relay, buttons are Schneider.

Abrasive feeder

• 170 liter capacity • High-precision sensors alert operators when they need to replenish sand • Safety relief valve • Working pressure: 0.2-0.3MPa • Water separator

No need electronic control, simple operation, reliable, maintenance-free. Can supply the cutting sand quantity . Need less than 0.2Mpa compressed gas pressure. Provide sand storage for the water jet cutter and automatically transfer the sand to the sand bucket. Can increase the automation of the equipment and reduce the labor intensity of the operator.

About company

Shandong WAMI CNC Technology Co.,Ltd.

Shandong WAMIT CNC Technology Co., Ltd is strive to supply China high quality water jet cutting machine. we supply:

1. 3 axis and 5 axis water jet cutting machine

2. 60000psi, 80000psi, 90000psi intensifier pump and 60000psi direct drive pump.

3. water jet cutting machine spare parts

4. abrasive sand removal system

5. all optionals about water jet cutting machine

Our water jet cutting machine is widely used in stone industry, glass industry, metal industry, composite materials(plastic, rubber, acrylic, foam), food industry and so on.

The company's products are exported to Europe, America, Africa, Asia and so on, and gradually establish a relationship from high quality, high quality, high service to trust.

Our Customer

Packaging & Shipping

1. Are you manufacturer or trading company? We are manufacturer of water jet cutting machine in JINAN city, Shandong, China. 2. What kind of material does your water jet cutting machine can cut? There are plenty materials our water jet cutting machine can cut, such as stone, ceramic, quartz, glass, foam, plastic, rubber, copper, brass, aluminum, mild steel, pre-hardened steel, titanium, inconel and cast alloy. 3. What's your CNC water jet cutting machine's max. cutting thickness? Generally speaking, if cut steel the max thickness of our water jet cutting machine can be up to 240mm, but we suggest cut no more than 150mm for smooth cutting. Now our Z axis distance is 170mm, we can customize for customers. Regular thickness please refer to: Marble is 0-120mm; granite is 0-110mm; tiles are 0-40mm; glass and mosaic is 0-80mm; steel, stainless steel, copper is 0-60mm; aluminum is 0-80mm; plastic, acrylic, foam is 0-200mm. 4. How we supply after-service? Some countries we have after-service department, we will provide local service, if have no local service, we will arrange engineer for overseas installation and training. The installation and training time is generally 7-10 days. And we also can provide installation videos. 5. What's your delivery time? Generally speaking is 30 days. if have stock, 7-15 days.