WAMIT 2*4M 30M/MIN moving speed 420Mpa 3 axis aluminum sheet CNC water jet cutting machine

https://www.alibaba.com/product-detail/Best-price-30m-min-stained-glass_62121545152.html?spm=a2747.manage.0.0.35b371d2VEv7ZS

our direct drive pump can save your 60%-70% electricity cost!

ADVANTAGES:

1. we promise 2 years( 2000 hours) warranty always. and have got CE certificate

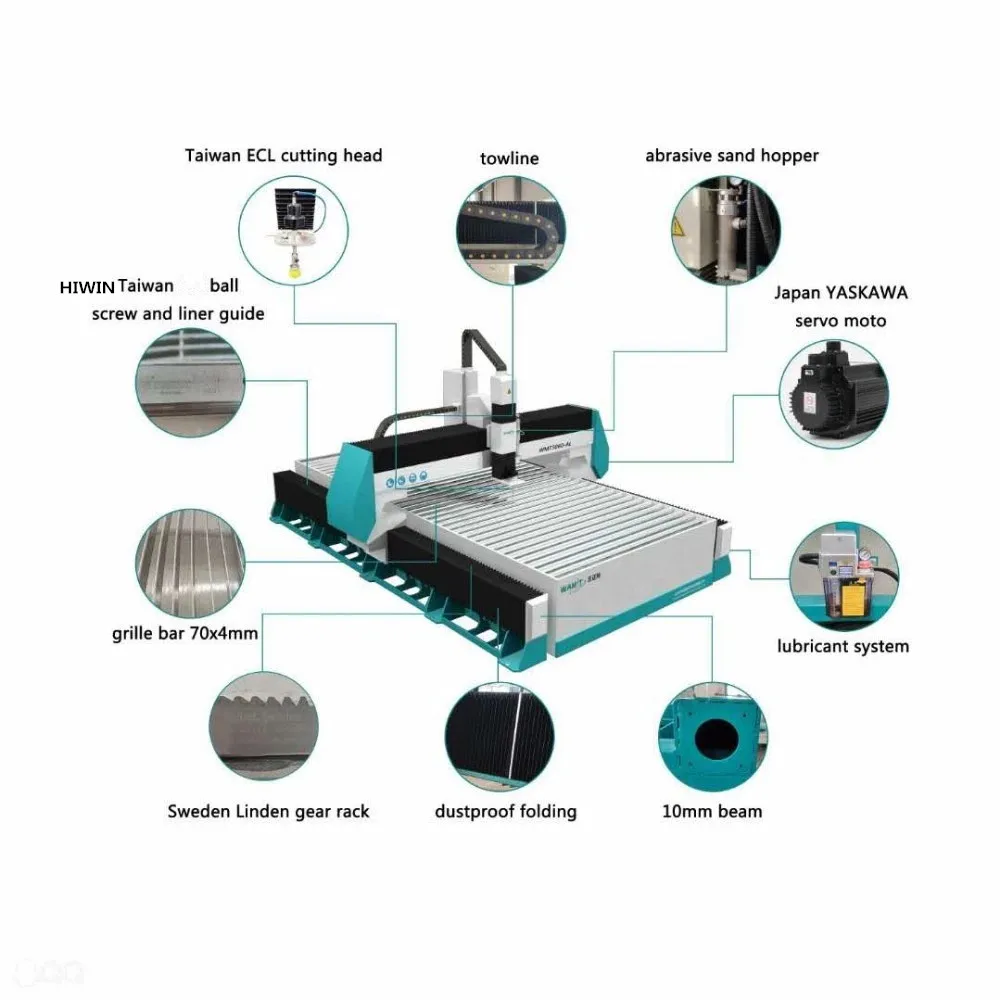

2. we use flow type ECL cutting head, the cutting efficiency is at least 10% higher.

3. the abrasive sand hopper beside the cutting head is also FLOW design.

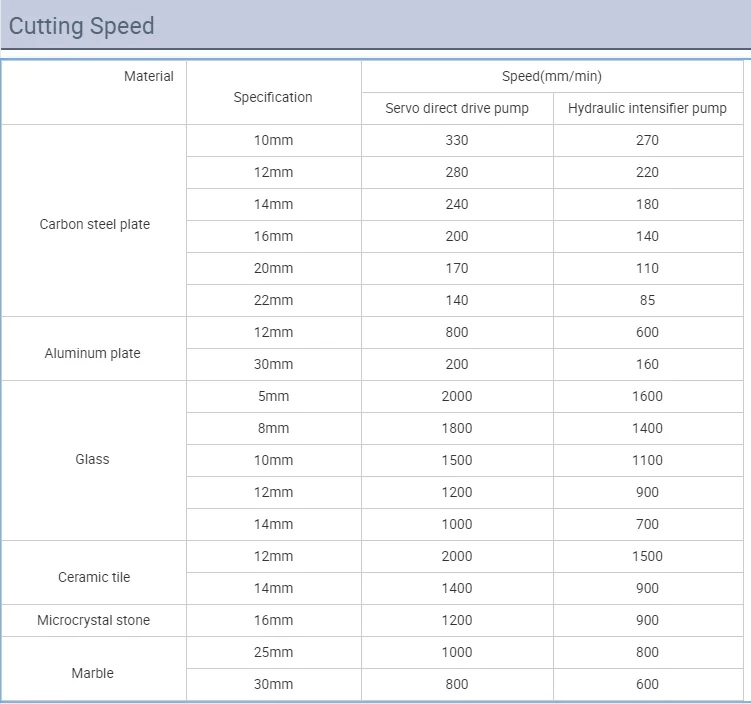

4. we have new technology that can make the machine moving speed is to 30m/min. normal speed is 6m/min as you see. if this

technology used in pure water cutting, the cutting cost will reduce 50%. if using other materials cutting like glass , marble,

steel, the cutting cost will also 20-30% reduced. but of course , the machine with this function price will be a little higher.

5. we use soft cover of the linear guider, can prevent dust away from the linear guider, so keep the linear guider keep precision

longer.

6. we assemble an auto oil feeding to linear guider, so customer needn't maintenance the linear guider always.

7. seperated body.

8. we will send a remote control pendent.

9. we have the world most convenient abrasive sand removing system. it can be used for any brand water jet cutting machine, maybe

you can promote this system in your country and other countries. please check the attachment.

11. we supply 420mpa pump with 37KW motor, but the price of the whole machine is very competitive now

12. we use variable pump, so can reduce electricity cost for customers.

13. we can do 220V and 415v also.

14. like height tracking system, positioning system , we can also provide.

15. all our components are SCHNEIDER brand

16. the motor and PLC are SIEMENS brand.

17. we can provide AB 5 axis with 10 degree and AC 3D 5 axis with 60 degree.

18. use 10mm steel for water tank supporter and use 8mm steel for beam, keep the machine working more stable.

19. use JAPAN YASKAWA servo motor.

20. imported TAIWAN HIWIN ball screw and linear guider

21. imported America intensifier and TAIWAN accumulator and high pressure assembly and low pressure assembly. if you have special

requests, we can also do.

22. we can provide 80Kpsi and 90KPSI intensifier pump and 60KPSI direct drive pump.

23. can make Touch screen

24. automatic calibration gantry perpendicularity

Can nearly cut all material:

Alloy Steel

Aluminum

Armor Plate

Brass

Boron

Bronze

Cast Iron

Cobalt

Copper

Exotic Alloys

Hastalloy

Hardened Steel

Hot Rolled Steel

Inconel

Kevlar

Magnesium

Mild Steel

Nickel AlloysStainless Steel

Steel Alloy

Steel Hardened

Steel Hard Rolled

Steel Mild

Steel Tool

Tantalum

Tin

Titanium

Tungsten

Wrought Iron

Zinc

Acrylics

Ceramics

Composites

Foam

Fiberglass

Kevlar

Mylar Laminates

Nylon

Plastics

Plexiglass

Porcelain

PVC

Rubber

Thermoplastics

Teflon

Urethane

Vinyl

Armor Plate

Bullet Proof Glass

Glass,Mirror Glass

Ceramic Tile

Granite

Limestone

Marble

Porcelain

Terrazzo

Hardwood

Main Features

1. Gantry type balanced design work table, solid and stable, higher strength

2. Work table of CNC motion mechanism and workpiece supporting adopts a split structure, which eliminates the influence of water gushing on cutting precision during cutting

3. X-axis,Y- axis use high quality LINDEN SWEDEN rack and pinion, TBI rail, which ensure the accuracy of bearing parts, stable conveying, hard-wearing quality. During cutting, it causes splashing sand and water. Fully enclosed lifting structure design in Z-axis prevents corrosion of lead screws and guides.

4. Lntegrated automatic lubrication system make the maintenance more automatic and easier.

5. All electric components are Schneider brand

6. Equipped with YASKAWA AC servo drive power and motor ( Japan brand), high accuracy, long service life.

420MPA INTENSIFIER PUMP

1.Type of pressurization is hydraulic. (The water is pressurized by using the fluid pressure intensification principle).

2.Max. oil discharge is 90 L/min

3.Max. water discharge is 3.8L/min

4.Max. diameter of orifice is 0.33mm

5.Max. operating pressure is 420MPa(60000 psi)

6.Continuous operating pressure is 350-380MPa

7.Power requirement : 37KW, 3 phrase, 380V/50HZ, can do 220V/415V.

8.Type of shift is electronic

9.Maintenance free accumulator is originally imported from TAIWAN.

10.Intensifier assembly are imported from USA

11.With SIEMENS motor and SIEMENS PLC and the motor is variable pump so that can reduce using cost.

12.all electric components are Schneider brand.

ABRASIVE SAND FEEDER

No need electronic control, simple operation, reliable, maintenance-free

Can supply the cutting sand quantity

Need less than 0.2Mpa compressed gas pressure. 220KG Sand can be used for 8-10 hours.

CNC CONTROLLER

CNC control, apply 21 inch LCD

Adopt specialized NCStudio water jet cutting software, have autosave function for next operation.

Apply SIEMENS PLC instead of relay, buttons are Schneidercan provide ITALY Imported ECS software which support more than 15

languages

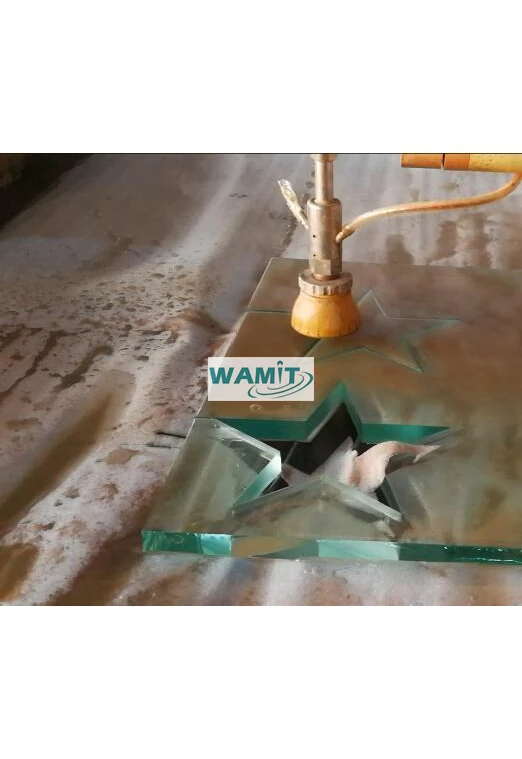

Cutting samples

Our Customers

Packing & Delivery

FAQ

1. Are you manufacturer or trading company?

We are manufacturer of water jet cutting machine in JINAN city, Shandong, China.

2. What kind of material does your water jet cutting machine can cut?

There are plenty materials our water jet cutting machine can cut, such as stone, ceramic, quartz, glass, foam, plastic, rubber, copper, brass, aluminum, mild steel, pre-hardened steel, titanium, inconel and cast alloy.

3. What's your CNC water jet cutting machine's max. cutting thickness?

Generally speaking, if cut steel the max thickness of our water jet cutting machine can be up to 240mm, but we suggest cut no more than 150mm for smooth cutting. Now our Z axis distance is 170mm, we can customize for customers. Regular thickness please refer to: Marble is 0-120mm; granite is 0-110mm; tiles are 0-40mm; glass and mosaic is 0-80mm; steel, stainless steel, copper is 0-60mm; aluminum is 0-80mm; plastic, acrylic, foam is 0-200mm.

4. How we supply after-service?

Some countries we have after-service department, we will provide local service, if have no local service, we will arrange engineer for overseas installation and training. The installation and training time is generally 7-10 days. And we also can provide installation videos.

5. What's your delivery time?

Generally speaking is 30 days. if have stock, 7-15 days.